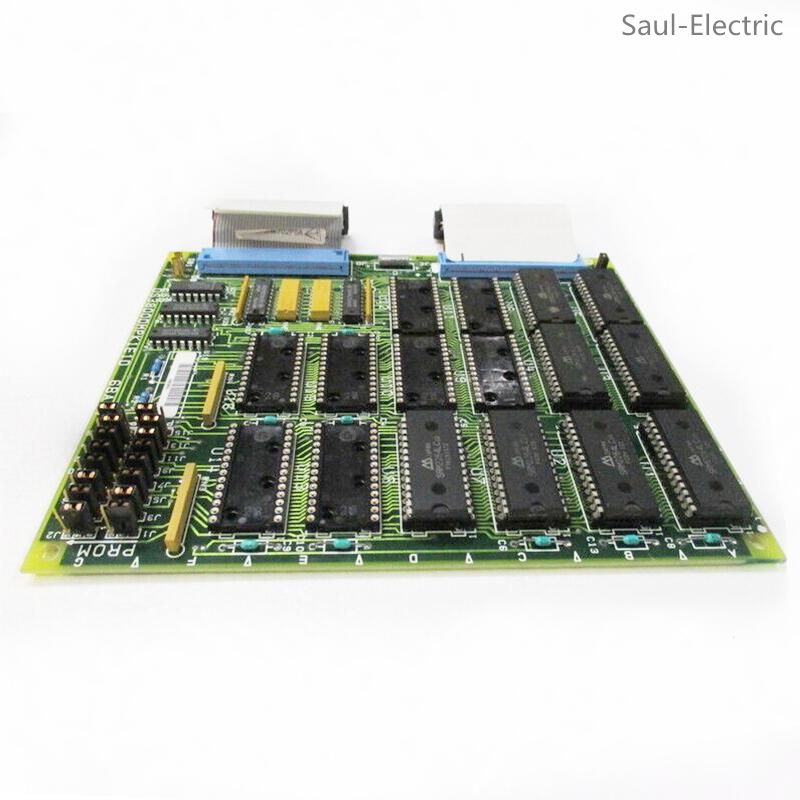

GE DS3800DCMC1 Digital Control Board

GE DS3800DCMC1

GE DS3800DCMC1 is a high-performance digital controller suitable for industrial automation control. It adopts advanced digital signal processing technology, which can achieve fast and accurate control, and has a reliable communication interface that can be networked with other devices for control.

parameter

Power supply voltage: 24V DC

Working temperature: 0 ℃~55 ℃

Storage temperature:- 40℃~85℃

Humidity range: 5%~95% (non condensing)

Communication interface: RS232、RS485、 Ethernet

Dimensions: 140mm x 160mm x 50mm

Weight: Approximately 1.5kg

Input ports: 16 digital input ports, 8 analog input ports

Output ports: 16 digital output ports, 8 analog output ports

application area

DS3800DCMC1 is widely used in the following fields:

Power system

petrochemical industry

manufacturing

Transportation

Environmental governance

advantage

High performance control: Adopting advanced digital signal processing technology, it can achieve fast and accurate control.

Reliable communication interface: Supports multiple communication protocols such as RS232, RS485, and Ethernet to ensure reliable networking with other devices.

Flexible configuration: Users can easily set parameters through graphical or command-line interfaces to meet the needs of different application scenarios.

High reliability: Suitable for various industrial environments, with high reliability and scalability.

GE DS3800DCMC1 is a powerful and widely used industrial control equipment, suitable for various industrial automation control scenarios.

Q: Are you a trading company or a manufacturer?

A: We are a trading company.

Q: Do you keep stock, or do you source products from external suppliers?

A: We maintain a large inventory and operate our own warehouse for efficient distribution.

Q: Do you guarantee that your products are 100% original and new?

A: Absolutely! No imitations, no counterfeits, and no outdated stock—only brand-new, authentic products!

Q: Do you sell discontinued or older products?

A: If there’s a newer model available, we’ll advise you to switch to the latest version. If an upgrade is not possible, we’ll inspect the existing product to ensure it’s still in good working condition. We’ll always be honest with you about its status.

Q: How long does it take for delivery?

A: If the products are available in stock, delivery typically takes 2-3 business days. For larger orders, it may take 5-7 business days after payment is confirmed. For non-standard products, the delivery time is generally 3-4 weeks or 6-8 weeks.

√ Premium service guaranteed!

√ Speedy processing and delivery!

√ Authentic, brand-new parts only!

——————————————————————————————————————————————————

Part of the main business

| 1. GE Mark VIe Series |

| · Models: IC697PLC730, IC697BEM731, IC697CPM915 |

| · Features: Modular and scalable architecture, high availability, real-time control, and extensive I/O options. Ideal for power generation and industrial applications. |

| 2. GE Mark VI Series |

| · Models: IC698CPE080, IC698PSU020, IC698CPE040 |

| · Features: Provides reliable control for various applications, including process control and power generation. Known for its robustness and flexibility. |

| 3. GE RX3i Series |

| · Models: IC695PSD040, IC695CPX928, IC695CPE302 |

| · Features: Part of the Versamax family, offering high-performance PLC solutions with modular and expandable design. Suitable for diverse industrial automation needs. |

| 4. GE Fanuc Series 90-30 |

| · Models: IC693CPU364, IC693PWR321, IC693ALG223 |

| · Features: Known for reliability and ease of use. Provides flexible configurations for various control applications. |

| 5. GE Fanuc Series 90-70 |

| · Models: IC697BEM731, IC697CPX928, IC697PLC730 |

| · Features: Advanced PLC capabilities with enhanced processing power and expanded I/O options. Suitable for complex automation tasks. |

| 6. GE D20 Series |

| · Models: D20 I/O, D20 RIO, D20 RPU |

| · Features: Distributed control system (DCS) offering versatility in handling complex processes with high reliability and performance. |

| 7. GE iFIX Series |

| · Models: iFIX 6.1, iFIX 5.9 |

| Features: Comprehensive HMI/SCADA software for real-time data visualization, process control, and historical data analysis. |